As a new type of semiconducting material, conjugated polymer has attracted great attentions from both academic and industrial communities for their great potential in the fabrication of cheap organic electronic devices via solution-based thin-film deposition technology. Poly(3-akylthiophene) has been widely used in field-effect transistors, polymer solar cells, and so on. Previous work has proved that the polythiophene backbone is mainly parallel to the substrate with either “plane-on” or “edge-on” orientation of the thiophene plane when deposited from solutions. It is necessary to construct continuous crystalline channels serving as uninterrupted transportation pathways for free charge carriers in the direction normal to substrate. Therefore, we prefer that the orientation of rigid polymer backbones is perpendicular to the substrate so that the thickness of the crystals could be substantially increased.

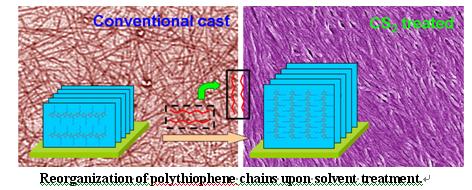

Poly(3-butylthiophene) (P3BT) is difficult to be dissolved in the most of common organic solvents at room temperature due to its short side chain. However, P3BT could be easily dissolved by a volatile solvent CS2. A slow evaporation of CS2 enables P3BT to evolve into a more thermodynamically stable state-Form II from its solution. And in Form II, polythiophene crystallizes into lamellae with width ~40nm and thickness ~15nm, both of which are pronouncedly larger than those of whisker crystals in typical Form I structure. More important in particular for large-area optoelectronic application, Yang et al. demonstrated a novel method controlled solvent vapor treatment which could induce conventional polythiophene whiskers deposited from the other organic solvents to transform into Form II lamellae by using CS2 as the vapor. Correspondingly, the rigid polythiophene backbones can re-adopt perpendicular orientation with respect to the substrate from the parallel orientation within convention whiskers. Definitely, the polymer lamellae in Form II adopt flat-on alignment, while whiskers of Form I adopt edge-on orientation. Controlled solvent vapor treatment could induce a preferred phase transformation while still preserves the uniformity of the pristine film. (Yang et al., Advanced Materials 2007, 19, 3594–3598)

|